Skycore Aviation presents this second article in a three series blog on UH-60 Black Hawk GE T700 engines. Our first article introduced the General Electric T700 engine and discussed the 4 sections of the engine, their purpose and key components. In this article, we will present questions and answers on refurbishing T700 engines from Tracy Ogle, the Vice President of Nebraska Gas Turbine Inc. (www.ngast.com) located in Hooper, NE.

Nebraska Gas Turbine Inc. (NGTI), a Skycore teaming partner, supports a wide variety of GE, Honeywell and Rolls-Royce helicopter engines and components and conforms to FAR Part 145 standards. NGTI leads the industry with the highest on-time delivery rates and backs its work with an industry-exclusive warranty.

When is a T700 engine refurbished?

The quick answer is when the T700 maintenance exceeds either the authorizations or the abilities of the maintenance team. A short list of the most common problems is:

- Oil leaks or consumption exceeding OEM (or other authority) limits

- Time Between Overhaul (TBO) items require replacement

- Low power levels that can’t be corrected

- Accident or Foreign Object Damage (FOD)

- Over-torque or temperatures that exceed limits (that require refurbishment per OEMs)

What are the first steps NGTI performs when receiving a T700 engine for refurbishing?

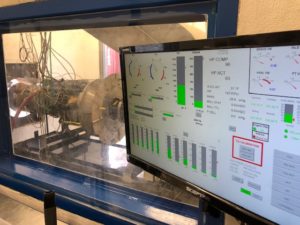

When NGTI receives a T700 engine (in an engine can or on a Black Hawk), we conduct a pre-induction inventory in accordance with our FAA Part 145 procedures. We induct the engine into the NGTI system, a process that includes a test cell evaluation to determine the induction ratings or possibly a maintenance operation check or maintenance test flight if the engine is on a Black Hawk. NGTI then assigns a work order and our team addresses the work scope (WS).

XT700-GE-700 Turboshaft Engine

How is an engine prepared for refurbishment?

Depending on WS, the next step is a review of the engine log book to determine consumable and TBO requirements. NGTI then puts together a Bill of Materials with requirements. We verify that consumables and TBO items are on hand or we place them on order.

What standard diagnostic tests are performed?

Typically, the first standard test is to flush the engine, to wash out impurities with particular attention to the compressor section. Then we conduct a Health Indicator Check (HIT check), which is powering the engine to determine if power levels have increased. Another standard test is to look at a sample of the oil to determine metal content. If the gears within the engine are “making metal” or causing chips, then excess internal wear on gears and other parts is occurring. NGTI also completes a hot end inspection and determines which Airworthiness Directives need to be complied with to be in compliance.

T700 engine diagnostic tests

How do you diagnose oil leaks or oil consumption that exceeds OEM limits?

The preferred method for discovering leaks is to run the engine in the test cell and visually check for seepage. We can also disconnect a drain line to determine which area of the engine is leaking the oil. This procedure can be performed while the engine is on the Black Hawk but it’s not the preferred method due to risk.

What are the typical causes of low power levels?

Some common problems causing low power levels are damage or excessive wear to engine parts such as

- Compressor blades and impellers

- 1st and 2nd stage turbine nozzle

- Gas Generator blades (GG rotors)

- Worn air seals

- Faulty power turbine shaft (torque stiction)

To minimize low power issues, compressor washes and HIT checks should be performed to predict these issues, as they are key to predicting engine operational levels.

What are the most common reasons that NGTI refurbishes engines?

The most common reasons we receive engines are low power, excessive trouble shooting and targeted part replacement by the customer with no remedies. Because T700 parts are very expensive, a few hours of targeted trouble shooting can save a customer thousands of dollars. Another reason, though not as common, are engines that are starting to fail oil analysis for metal and engines that need TBO parts replaced.

Skycore Aviation

Skycore Aviation is an international helicopter personnel services and UH-60 Black Hawk provider. Our knowledge and experience enable Skycore to provide personnel and turnkey solutions for helicopter programs tailored to meet customer operations, maintenance and training needs. Follow us on LinkedIn, Twitter and Facebook to stay atop of the rotary wing industry.